Archimedes Screw History – Traditional use of the screw has been as a pump

To reclaim land as with this windmill pump in Holland.

To irrigate land – past and present day.

To pump sewage.

To pump fish in the aquaculture industry.

The Archimedes Screw as a generator – Technology Overview

At least 400 Archimedes screw generators (ASGs) have already been installed in Europe since 1993 (Lashofer et al., 2012) and more are under construction, however there are currently few installations outside Europe. GreenBug connected the first ASG to the North American power grid in September, 2013, near Waterford, Ontario.

- Simple, robust, reliable, few parts.

- Doesn’t require fine intake screening for debris as it passes all but the largest of debris, making it less maintenance with little to no trash rack cleaning. There is a course intake grate to keep out the very large debris and for safety purposes.

- Simple weight of the water turns the screw, which turns the gearbox which turns the generator. For example, there is approx. 6000 lbs of water in the Fletcher screw at any one time.

- The diameter is increased to accommodate larger flows.

- The length is increased to accommodate larger heads.

- The screw needs 1 meter of head as a minimum, and can go up to 10 meters in some cases, but the screw is most likely to be used on heads of less than 5 meters.

- The screw is classified as a lower head, higher flow technology but the effective higher flow is going to be limited to the diameter of screw that can be transported down the road without incurring special costs for excess height, which is about 4 meters in diameter, thereby limiting the upper flow range of a single screw to around six and a half cubic meters per second approximately. Beyond this a second screw would have to be used to accommodate more flow or extra transportation costs incurred.

- ASGs have greatest potential at low head sites (less than about 5 meters of head), and unlike conventional reaction or impulse turbines, have the potential for maintaining high efficiencies even as the head approaches zero.

- Each screw is custom made for the watercourse flow and head and this is easily done. Manufacture of the screw takes about a week.

- The generator is an off the shelf gear-motor that industry would use so it’s robust and proven.

- Our grid tied screws are “Asynchronous induction Generators”, and we can connect to either 3 phase or single phase depending on the service available.

- Grid tied screws can be used either in a FIT connection or Net metering connection as Fletchers is.

We now have 2 different “Off grid” or stand-alone systems for remote areas.

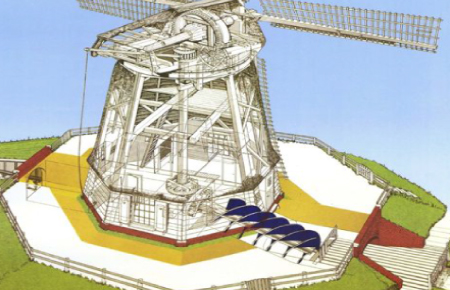

How the screw can be used at existing water control structures

Our preference is to install beside the main existing water control concrete structure and not install on it because while installation on an existing weir is possible, it raises engineering questions about the weir/dam structure itself and there is also the issue about potentially decreasing the flood flow capacity of the weir structure which has to be studied. We prefer to bypass these extra costs because micro hydro does not have the scale to withstand these types of costs.

Usage and refurbishment of existing channels and intakes is possible to reduce site disruption and civil construction as it was at the Fletcher site. We utilized the old existing turbine intake and refurbished it, cleaned out the old channel and simply added an addition on the end. In this case we did not utilize the old mill tail race, but instead turned the screw 90 degrees to have the water exit for the screw enter the watercourse immediately below the weir, in order to eliminate any depleted reach that would have been caused by using the old tail race. All the work on the addition was done on dry ground, and when completed the earth between the screw exit and the watercourse was removed.

Cold weather performance of the Archimedes Screw System

- While the top surface of the water may freeze, the water always flows, and to prevent icing of the screw as it rotates we have a simple air seal arrangement at the intake and at the water exit. At the entrance is a simple concrete slab that extends just below the water and at the water exit, stop logs do the same thing. This prevents cold air from entering the screw chamber and generator room. With the thermal mass of the water and the small amount of heat emitted from the generator, the generator room stays just above freezing without any external heat source.

- The Fletcher installation worked throughout one of the coldest winters in Ontario history with no icing issues (2013-2014) in spite of an uninsulated generator room.

- Our thermal modelling will tell us when we need to provide additional insulation in the generator room.

- As installations get larger the generator size relative to the generator room tends to increase therefore freezing is less of a concern, and venting in the summer is a larger issue.

Small 500 Watt capacity Archimedes Screw generator of the Open Complete model type sitting on small weir spillway.

Technical issues that make the Archimedes Screw generator environmentally attractive.

- Bottom draw capable – design of the intake can accommodate bottom draw of flow.

- Lower bearing – is a proprietary water lubricated composite or a proprietary submersible roller bearing assembly that is not grease fed. The lower submersible bearing in the screw at Fletchers is a simple water lubricated composite bearing.

- Upper bearing – is a simple bearing with an auto lubrication device attached to grease it occasionally, but there is nothing to spill and this bearing is out of the water.

- Upper gear box – contains food grade oil. While the gearbox isn’t near the water, the food grade oil is an extra precaution we take.

- The protective coating on the screw is a two part epoxy which after application and hardening the coating is chemically inert.

- Slow tip speed – The reason that rpm decreases as screw diameter increases is to keep the tip speed (the outer edge of the flighting) safe for fish. We follow the UK Environment agency’s guidelines that have been developed over several hundred installations and studies.

- Compressible Rubber bumpers – as additional fish protection, we install rubber bumpers on the leading edge of the flighting so that it absorbs any impact with a fish entering the screw. We use compressible rubber bumpers as standard practice.

- Acts like an elevator not a blender – The screw acts like an elevator for the water than enters, not a blender. As the screw turns, each flight takes a huge “bucket” of water that is then trapped between successive flights. The water in this bucket remains relatively stationary in the bottom of the screw as the screw turns. Therefore any fish that do enter get lowered from top to bottom with the water. This can be seen in the diagram below.

- Big water buckets – The “water bucket” or space between any two steel fights on the screw is very large. The chamber of water available for fish while being lowered is very large. This can be seen in the examples diagram below

- Absence of extreme pressures or shear stress associated with more conventional high head turbines – The Archimedes screw does not work based on the same water pressure concept as do traditional turbines, there is no increased water pressure or high rpms associated with water moving through the screw as there is with traditional turbines.

- In one of the studies the effects of turbulence and shear stress on fish orientation within the screw compartments was assessed using camera footage of fish passing down the screw. No adverse effects were observed and this was deemed to show that the startle response of fish would not be affected by passage down the screw.

- The result of all of the above is safe downstream fish passage.

- In another study In order to assess attraction of adult salmonds to the outflow, underwater cameras were positioned to record fish approaching the outflow. Twenty-five fish were seen by the cameras, spending an average of 8 minutes in the outflow area. No fish were seen attempting to jump up the screw.

- True run of river – the screw only takes water that would have otherwise went over the weir to generate electricity. Flows beyond the screw capacity, continue to flow over the weir. If at any time the screws flow capacity exceeds the watercourse flow, this is when the sluice gate can become active to restrict flow to the screw to maintain the target water level at the weir.

- Increases dam maintenance by having parties with a vested interest in the Dam structures.

- Increases flood flow capacity of the site – when installed off to the side of the main weir structure, the screw adds to the flood flow capacity of the site.

- 100% of the water is returned to the water course – part of the flow just travels down the screw instead of over the weir.

- Does not have to affect the water levels above or below the water control structure – we say it doesn’t “have to”, but we can if this is desired for some environmental reason. For instance. While the sluice gate on the screw intake can be used to maintain a target water level at the weir to ensure a true run of river system, this could be changed to allow the screw to lower water levels below the weir crest by a certain amount if desired. This would no longer be true run of river, but may be desirable in some situations such as a planned draw down of water levels to allow for flood flows.

- Hopefully screw installations reduce other forms of generation that are non-renewable.

- Many low head dams are near or in small communities due to historical origins allowing energy production where it is used and connection to distribution lines with no need for transmission lines.

- Studies available:

- Fish Monitoring and Live Fish Trials – Phase 1

- Fish Monitoring and Live Fish Trials – Phase 2

- Fish Monitoring and Live Fish Trials – Phase 3

- Archimedes Screw Risk Assessment – strike and delay probabilities

- Archimedes Screw Leading Edge Risk Assessment

1 cubic Meter = 1000 liters = 264 U.S. Gallons

Economics

- One of the biggest economic challenges relates to the fixed and semi-fixed soft costs and processes of development. They put a disproportionate burden on small projects. Site assessment costs, civil and geo-technical engineering costs, approval related costs, electrical engineering and connection assessment related costs. These costs wouldn’t vary much for either a 7.2kW site like Fletchers or for a 150kw site. Either of these projects likely bear a disproportionate amount of soft costs relative to larger projects based on the fact that many of these tasks are performed exactly the same as they would be for larger projects.

- Therefore to make micro hydro possible something has to change, something has to be done differently from the current processes used for larger hydro project development in order to change the economics. Our focus therefore has been to attempt changes that reduce cost or waste in several ways;

- In order to reduce project design costs we have developed our own in house model working with several universities. The model inputs are head and flow duration data, and the model solves (in about a week) to find the optimal screw configuration and size that will maximize the rate of return on the project. The model considers approximately 20 million different possible screws, the cost of each, the revenues of each given the head and flow duration data and the rate of return of each. It also produces Solidworks drawings for the chosen screw. This not only eliminates most of the soft costs but it ensures that the last drop of rate of return is captured.

- To reduce the expensive site assessment costs necessary to determine head and flow duration data at many ungauged sites we are involved with two additional university research projects, both of these projects will increase the accuracy of our head and flow duration data, increase the speed with which a site assessment can be completed and eliminate much of the time and effort in collecting data in order to improve project economics.

- To understand the current nature of existing processes in an effort to eliminate waste and streamline processes we have vertically integrated into the design, manufacture and installations of systems as well as all approval processes with a focus on documenting and streamlining processes with a focus of making them standard and capable of installing a system a week. This approach has yielded large gains to date.

- We have supported OWA’s (Ontario Waterpower Association) efforts to streamline the Class EA process for waterpower projects as it relates to smaller projects.

- We have supported MNR’s and other government bodies efforts any way we can to understand what and how we are doing things in an effort that understanding may bring new approaches.

- Our efforts to date are providing site owners with returns of between 8 and 12% IRR.

Old Technology – New Application

The Archimedes Screw has been used for pumping water for over 2000 years. Applying the principle in reverse, the same equipment now offers a new method for generating power from water, providing a fish friendly and highly efficient alternative to a conventional turbine. Each Archimedean Screw hydropower system is manufactured to be site-specific, with a choice of designs depending on which is the most appropriate and cost-effective for each individual site.

Why we use Archimedes Screw Generators

The power that we can be derived from a hydro site is a function of the head, or height, of the vertical drop and the volume of water in the river. The bigger the head and the bigger the volume of water the more power can be generated.

Hydro turbines at any specific site are designed to capture the greatest possible head and the greatest possible volume of water – Turbines are designed to turn when water goes through them and it is the turning motion which generates electricity.

There are several types of hydro electric turbines. All the turbines have a gearing mechanism that drives the generator, but they differ in the manner by which the energy is extracted from the fall of water and converted into mechanical rotation. The mechanical rotation is then converted into electrical energy.

We use Archimedes Screws because of these features;

Fish Friendly –

It, and the Waterwheel are the least harmful to fish of all the turbine types. Scientific evidence (Fish Monitoring and Live Fish Trials Phase 1, Sept 2007 and Phase 2, April 2008, Fishtek Consulting) shows the safe passage of fish down the screw while it is operational. The Archimedean Screw and the Waterwheel operate at normal atmospheric pressure while other turbines, for instance the Kaplan, operate by forcing water at high pressure into the system. In addition, the screw turns at a low velocity of approx 28 rpm. This, together with the operation of the turbine under normal atmospheric pressure, enables the safe passage of fish through the system.ACHIMEDEAN SCREW

– Slow rotation – No blade strike damage to fish.

– Normal water pressure = No fish swim bladder damage.

– Large water chambers = Safe passage for fish of all sizes.

– Smooth flow = No disorientation of fish.

– No fish screening is required.

CONVENTIONAL TURBINE

– Fast blade rotation = High rate of injury to fish.

– Pressure changes in water = High rate of injury to fish.

– Fine fish screening required = increase installation & running costs.

Although widely in use throughout Europe and the U.K. for some time now, the Screw is a newcomer in North America.

On the basis of previous studies carried out in Europe which supported the claims to fish-friendliness, the first Ontario Screw installation was installed in 2013.

Literally thousands of fish passages have been monitored and recorded using underwater cameras at the intake, inside the chamber of the Screw itself and at the outflow to assess the effect of the Screw on salmonids (including smolts and kelts), brown trout and eels. The trials looked at fish passage across a broad spectrum of sizes and turbine speeds, possibly the most impressive of which was the safe passage of a kelt measuring 98cm in length and weighing 7.6kg.

The European studies conclude that the Archimedean Screw turbine is indeed fish- friendly with no adverse physical effect on fully grown fish or kelts; at most 1.4% of smolts sustaining limited and recoverable scale loss (NB ‘at most’ because these were wild fish and quite likely to have sustained some scale damage prior to entry into the turbine) and just 1 out of 160 eels (0.64%) suffered minor and recoverable pinching

to the tail. In addition, behavioural and migrational patterns across the species have been shown to be entirely unaffected by the turbine.

Fish safely entering the top of screw as the screw turns slowly.

No Depleted Reach –

this is measured as the distance between where the water leaves a river to enter a hydro system and where the water goes back into the river. Clearly by taking a given volume of water out of a river, there will be an impact upon the natural ecology of the river bed. A large depleted distance may therefore compromise the ecology of the river bed. The smaller the depleted distance, the less impact there will be upon the fish and wildlife ecology. The Archimedean Screw has the lowest depleted reach because it is placed alongside a river weir – the water enters the system from just above the weir and returns to the river just below the weir. While more traditional turbines such as the Kaplan can also be placed alongside the weir, the Kaplan does not have the advantage of being considered ‘fish friendly’.

Visibility –

because the Archimedean Screw is visible, there is an educational benefit to this type of turbine. It can be readily viewed while in operation and the turning motion and the generation of electricity is immediately obvious.The educational aspect of the Archimedean Screw ought not to be underestimated.

Cost efficiency –

The Archimedean Screw is the most cost efficient option. A report funded by Yorkshire Forward (Archimedes’Screw:Copley Hydro Power Generator) showed that the costs of installing a Kaplan turbine in relation to an Archimedean Screw are higher per kW installed.

Overall efficiency –

The Archimedes Screw has a high level of overall efficiency which is maintained across a huge range of flows, resulting in a single speed screw continuing to generate power down to approx. 30% of the maximum flow capacity.

Low Maintenance –

The Archimedes Screw generator is a simple, robust machine with low maintenance requirements because it has only a few wear parts. Due to the simple and robust design. Screw generator installations require minimum maintenance.

No fine screen necessary –

Only a simple 120mm(6″) bar screen is used to prevent large items from entering the screw generator. This saves costs, prevents head loss and allow fish passage.

Coarse intake grate allows fish and small debris to pass while safely keeping out larger objects.

Wide range of flows –

The screw generator is capable of handling flows from 100l/s – 10m3/s each.

Wide range of heads –

Any head from 1m to 10m

Minimal Cleaning necessary –

Cleaning of the screw generator is not necessary. The need to make sure that no fish or debris enters into the Kaplan system requires a fine mesh screen at the water inlet channel. This has to be regularly cleaned and is recommended to be accompanied by an automatic trash cleaning device. This will increase the capital cost and maintenance of a Kaplan turbine project. In contrast, floating objects, debris and fish simply pass through an Archimedes Screw with no need for expensive fine screening. There is a coarse intake grate with 6″ x 6″ openings on the Archimedes Screw which can require periodic cleaning to remove large debris but can be minimized with proper placement of a floating boom

Operational Range of an Archimedes Screw System

- Capacity (flow) from 100 to 10,000 (10 m3(s)) litres per second.

- Hydraulic head from under 1m to 10m.

- No head loss from fine screens or pressure pipes.

- Fully operational down 30% of maxiumum flow (single speed systems).

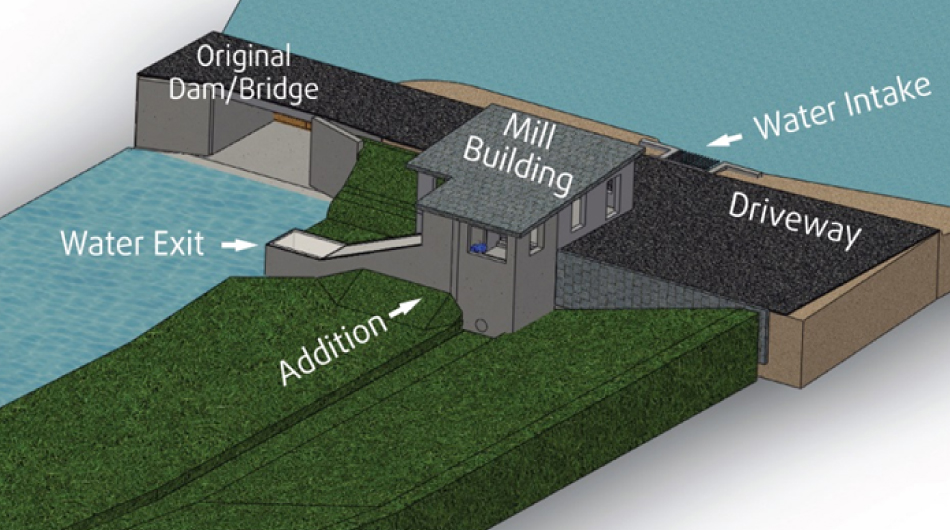

Overhead View of Typical an Archimedes Screw Generator Installation

Advantages of Archimedes Screw Small Hydropower Systems

- Archimedes screw systems are micro hydro systems and even when installed beside existing small dams/weirs, the dams/weirs create only a small impoundment and many times no noticeable visual impoundment at all. Therefore there is no inundation of wildlife or surrounding land and minimal increase in water temperature.

- Archimedes screw systems are run of river systems and therefore the timing and variation of water flows is unaffected. Archimedes screw systems do not attempt to “store up” water in a reservoir.

- Archimedes screw systems produce hydropower cost effectively. This means that small dams/weirs are now useful valuable assets once again as they were historically and now a valuable assets as we clean up our air, renew our economy and reduce our reliance on foreign oil. Small dams can be functioning, economically viable hydropower dams.

- Archimedes screw systems do not obstruct the movement of sediment, woody debris or nutrients. Because half of the diameter of a screw is above water level and half is below it this means that Archimedes screw systems intake extends below the crest of any small dam/weir and therefore allows movement and passage of sediment, woody debris and nutrients that would normally accumulate behind the small dam or weir. This is also facilitated by the fact an Archimedes screw systems only has a very course intake grate with openings of 6″ by 6″. It does not have fine screening.

- Archimedes screw systems restore downstream fish passage at small dam sites and they can be installed with fish passages to restore upstream fish passage at the same time if environmental authorities want this to happen. (Note contrary to common belief this is not always the case.)

Archimedes Screw Generator Applications

- Cooling water outlets from power stations

- Industrial process water (e.g. paper/steel mills

- Old mill sites

- Existing small weirs/dams

- Replacement of waterwheels and other types of generators.

- Water treatment outfalls

- Anywhere there is a suitable head and flow